Typical Obstacles in Foam Control and How to Get rid of Them Efficiently

Typical Obstacles in Foam Control and How to Get rid of Them Efficiently

Blog Article

A Comprehensive Guide to Applying Foam Control Solutions in Your Workflow

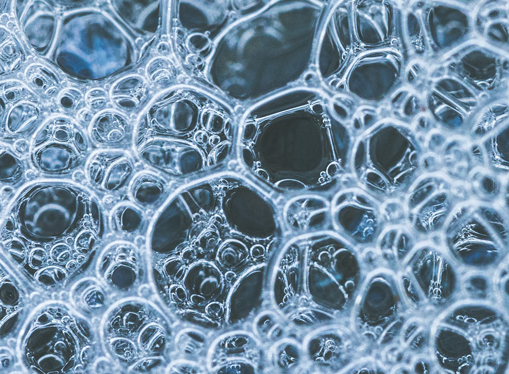

Reliable foam control is a critical element of functional performance that frequently goes overlooked. Comprehending the ins and outs of foam generation can considerably influence both performance and product quality. This overview outlines the various obstacles postured by foam and the diverse solutions readily available, offering a framework for selecting and carrying out one of the most suitable methods. By analyzing key factors such as application compatibility and workers training, companies can maximize their foam monitoring efforts. As we discover these parts, the potential for transformative improvements in your operations comes to be obvious. What actions will you take next?

Understanding Foam Obstacles

Foam challenges are a substantial problem across different sectors, influencing functional performance and item top quality. The development of too much foam can hinder procedures such as blending, transportation, and storage space, resulting in increased downtime and waste. In fields like food and beverage, pharmaceuticals, and petrochemicals, foam can hinder manufacturing lines, causing product incongruities and contamination threats.

In addition, foam can obstruct tools performance, resulting in expensive fixings and upkeep. In wastewater therapy, foam can interfere with clarifier operations, resulting in lower treatment efficiency and regulatory conformity problems.

Understanding the underlying reasons for foam generation is crucial for effective administration. Aspects such as surfactants, temperature fluctuations, and anxiety degrees can all contribute to foam manufacturing. Identifying these aspects allows sectors to implement targeted strategies that decrease foam development while keeping product integrity.

Kinds of Foam Control Solutions

Mechanical options entail the use of devices such as foam skimmers or defoamers. Chemical options, on the other hand, include the application of defoaming representatives-- substances that disrupt the foam structure, leading to its collapse. Foam Control.

Finally, functional methods concentrate on procedure changes. This may involve modifying devices parameters, such as temperature and pressure, or changing the circulation prices of fluids to decrease foam generation. Executing good housekeeping techniques can likewise mitigate foam development by minimizing impurities that add to foam stability.

Picking the suitable foam control solution includes examining the certain needs of the procedure, including the kind of process, the attributes of the products included, and safety factors to consider.

Selecting the Right Products

Selecting the best foam control items calls for an extensive understanding of the certain application and its distinct obstacles. Variables such as the kind of foam, the setting in which it takes place, and the preferred outcome all play crucial functions in product option. Foam Control. For instance, in sectors like food processing, it is imperative to pick food-grade defoamers that reference adhere to security laws while effectively taking care of foam.

In addition, think about the viscosity of the fluid where the foam trouble exists. Some items are formulated for low-viscosity applications, while others are tailored for thicker fluids. Compatibility with existing processes is an additional important facet; the chosen foam control agents should incorporate seamlessly without interfering with general operations.

One more vital aspect is the technique of application. Some products might need dilution, while others can be applied directly. Analyzing the simplicity of usage and the needed dose can give understandings right into the product's performance and cost-effectiveness.

Execution Techniques

Successful application methods for foam control solutions call for a systematic method that lines up product choice with functional needs. The initial step includes an extensive analysis of the processes where foam takes place, recognizing certain locations that demand treatment. By engaging cross-functional groups, consisting of design, high quality, and manufacturing guarantee, organizations can collect understandings that educate the option of the most reliable foam control products.

Following, it is important to establish clear purposes for foam reduction, making certain that these goals are attainable and measurable. This might entail defining acceptable foam levels and the timelines for application. Educating workers on the residential or commercial properties and application methods of selected foam control agents is equally essential, as correct use navigate to this website is vital for optimal outcomes.

In addition, incorporating foam control options into existing process needs mindful preparation. Organizations ought to establish a phased execution plan, allowing for changes based upon first end results. Routine interaction and feedback loops with team entailed in the procedure will facilitate prompt problem-solving and foster a culture of continuous improvement. Inevitably, a well-structured approach will certainly boost functional performance while successfully handling foam-related challenges.

Surveillance and Assessing Effectiveness

Surveillance and reviewing the effectiveness of foam control remedies is essential for guaranteeing that implemented methods yield the wanted results. This procedure entails organized data collection and evaluation to evaluate the performance of foam control representatives and strategies. Trick performance signs (KPIs) need to be established prior to implementation, enabling a clear baseline versus which to gauge progress.

Evaluating performance additionally calls for regular testimonials of foam control procedures and agent efficiency. This can be completed through tasting and screening, allowing operators to identify if present options are fulfilling operational needs. It is essential to solicit comments from team participants who interact with these systems daily, as their insights can reveal operational subtleties look at this now that quantitative information may ignore.

Eventually, a structured monitoring and evaluation structure assists identify necessary modifications, making certain that foam control options remain effective, inexpensive, and aligned with business goals.

Final Thought

In conclusion, reliable foam control options are necessary for enhancing functional efficiency and maintaining item quality. A complete understanding of foam difficulties, incorporated with the choice of suitable products and application methods, facilitates the successful management of foam generation. Developing quantifiable KPIs and spending in employees training further boost the performance of foam control procedures. Routine surveillance and examination ensure continual renovation, ultimately resulting in a much more streamlined and productive functional setting.

Carrying out great housekeeping techniques can likewise alleviate foam development by minimizing pollutants that contribute to foam stability.

Selecting the appropriate foam control products requires an extensive understanding of the specific application and its one-of-a-kind difficulties (Foam Control).Effective implementation strategies for foam control options require an organized strategy that straightens product option with operational requirements.In verdict, effective foam control services are important for enhancing operational effectiveness and keeping item high quality. A detailed understanding of foam challenges, integrated with the option of ideal products and application approaches, helps with the effective administration of foam generation

Report this page